Lab / Engineering Services

We can provide customers the following services:

- Complete Film Analyzation

- Reverse Product Engineering

- Product Development

- Process Analytics

- Quality Assurance

Laboratory / Quality Control Testing

The latest in physical and analytic testing methods are utilized to help ensure product integrity and success. Our phased analysis and cost-reduction systems assist us in meeting and exceeding customers’ expectations.

- DSC

- FTIR/ATR

- Optical Microscopy

- Opacity

- Gloss/Haze

- Tensile Strength/Elongation

- Dart/Puncture

- Tear

- Hot Tack/SIT

- Secant Modulus

- Shrink Characteristics

- Seal Initiation & Seal Strength

- Thickness Profiling

Lab Equipment

Polymer Packaging utilizes the following lab/R&D equipment:

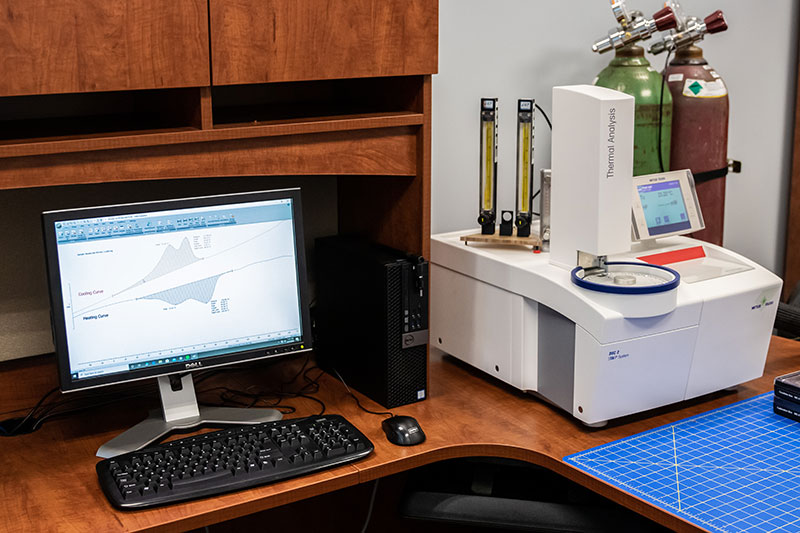

DSC (Differential Scanning Calorimeter) Testing

The DSC is utilized in all stages of manufacturing from quality assurance and production through to research and development. It is used to help identify exact chemical structures and structures.

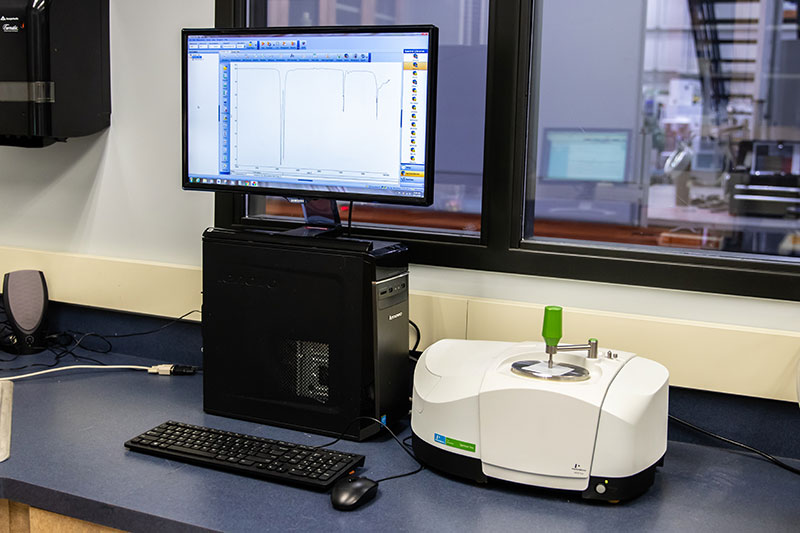

FTIR/ATR (Fourier Transform Infrared/Attentuated Total Reflectance)

Fourier-transform infrared spectroscopy (FTIR) is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. An FTIR spectrometer simultaneously collects high-spectral-resolution data over a wide spectral range. It identifies the exact chemical structure (based on the periodic table) of a product. It is particularly valuable in reverse engineering a product during the R&D stage.

(ATR) Attenuated Total Reflection testing is mainly used for studying polymer surfaces, The ATR is a special accessory unit which can be used with the FTIR spectrometers.

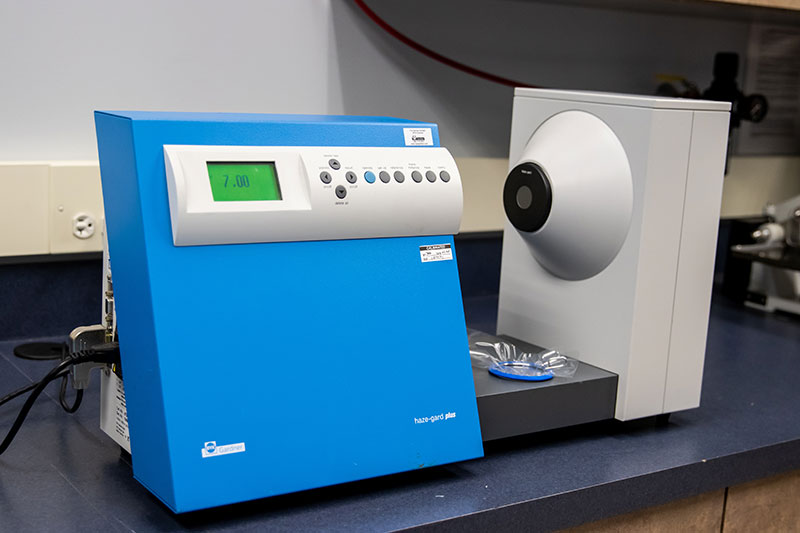

Haze Meter Testing

Haze is cloudiness of a product caused by the scattering of light. Light may be scattered by particles suspended in the material, such as pigment particles or contaminants, or by an imperfect surface caused by dirt or a fine texture. Haze is an important appearance attribute which can be quantified and used to assess the quality of flexible packaging film. With a single pass of the light source through your material, the system measures light diffusely scattered for transparent or slightly translucent materials.

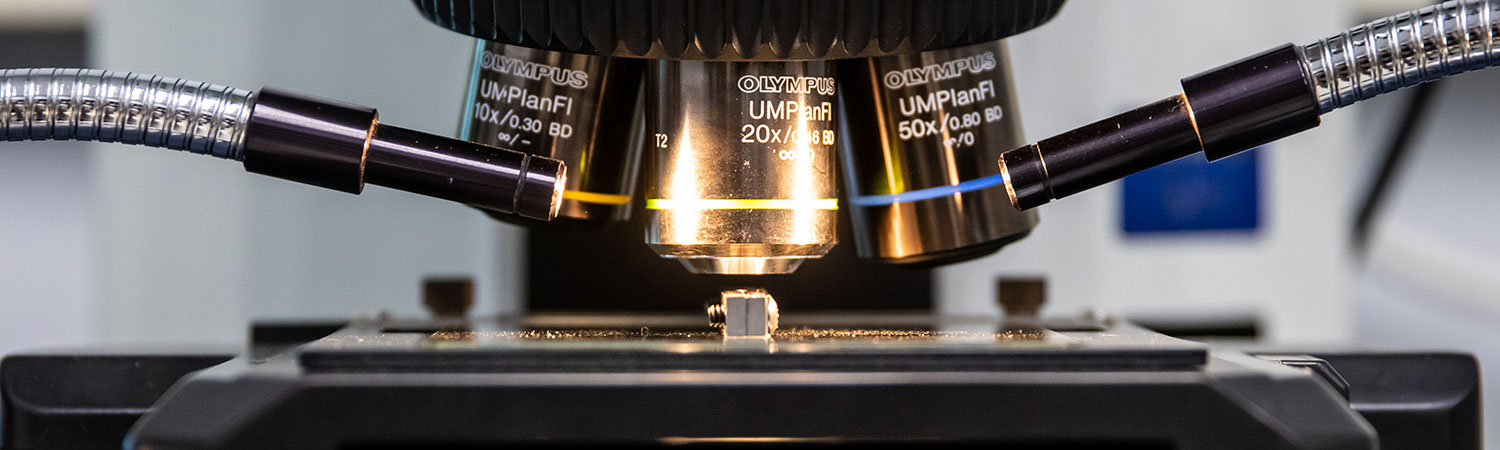

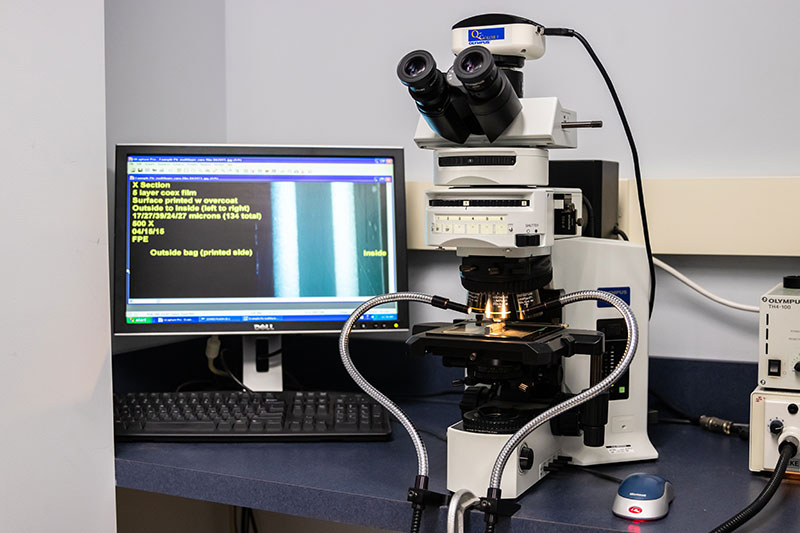

Microscopic Structural Analysis Testing

Microscopy analysis helps to determine the structure and properties of materials, composites and products. Microscopy magnification can be used to obtain chemical and physical information about a polymer’s structural features. This is essential as it provides insight which can be related to the performance of the material. Our experts use microscopy to support new material research and development, to process and property optimization, to investigate polymer morphology and microstructure, composites structure, failure analysis, degradation and a wide array of problem solving.

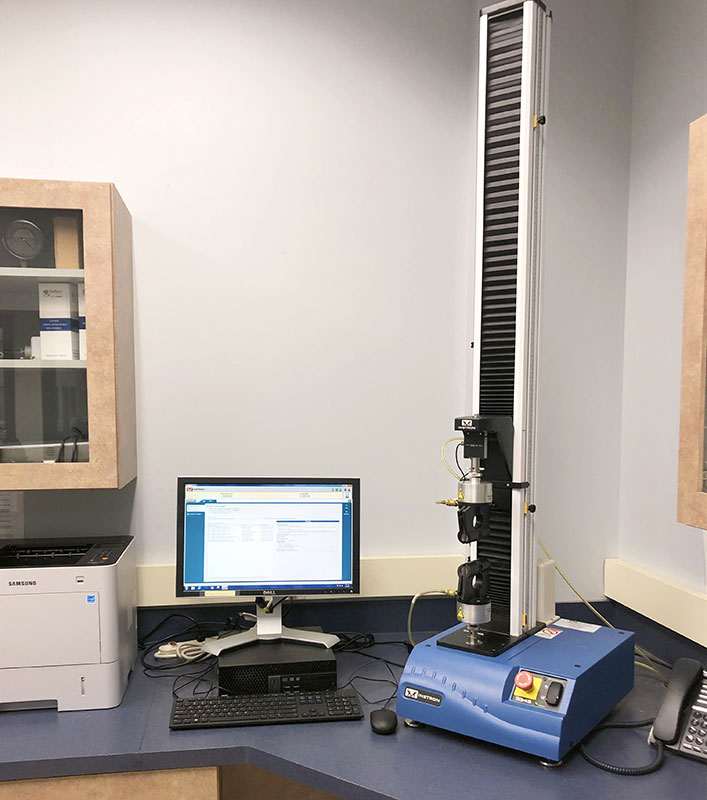

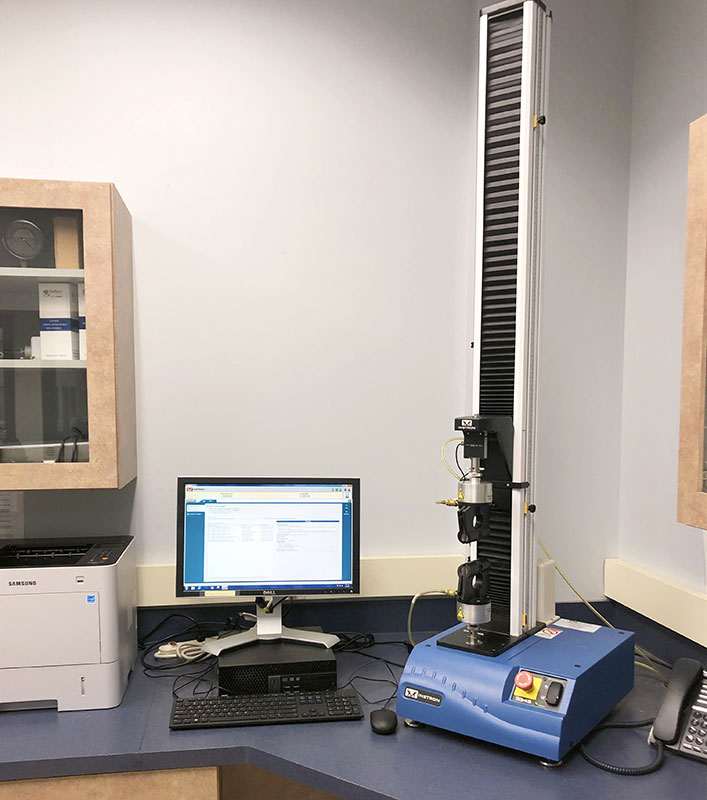

Instron Tensile Testing

A tensile test applies tensile (pulling) force to a material and measures the response to the stress. By doing this, tensile tests determine how strong a material is and how much it can elongate.

Melt Flow Index Testing

Melt flow index is a measure of the resistance to flow (viscosity) of the polymer melt at a given temperature under a given force for a predetermined period of time. The Melt Flow Indexer, often abbreviated as "MFI", is used to test the melt flow resistance (MFR) of a wide range of thermo-plastic materials. Another application for MFI testing is in support of failure analysis. A sample from a failed product can be tested for comparison to the material specification.

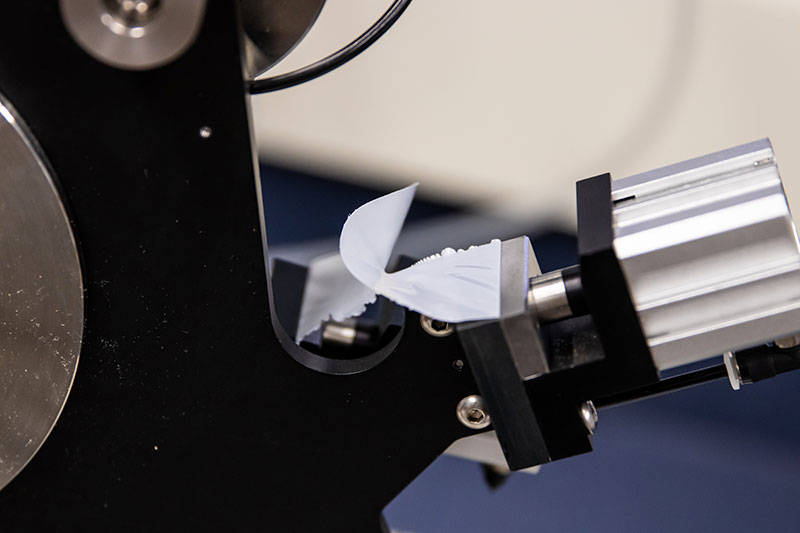

Elmendorf Tear Testing

Elmendorf Tear testing determines the force required to continue the tearing of an initial cut in sheet materials such as paper, plastic film, textile and non-woven materials.

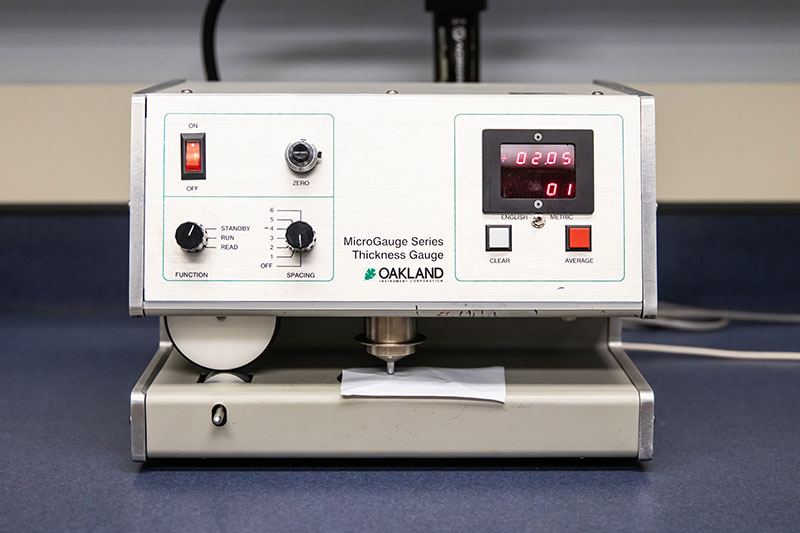

Micrometer and Gram Scale Equipment

A Micrometer (Gauge Profiling) provides a means for measuring a thickness dimension. Accurate measurement of thickness can be critical to meeting specifications and characterizing process, product, and material performance. Our Gram Scale equipment offers reliable and high-precision weighing, easy transfer, export and reporting of results and audit-proof documentation.

OTR/MVTR (Oxygen Transmission Rate/Moisture Vapor Transmission Rate) Testing

OTR/MVTR (Oxygen Transmission Rate/Moisture Vapor Transmission Rate) . OTR is the measurement of the amount of oxygen gas that passes through a substance over a given period. It relates to the permeation of oxygen through packaging. MVTR is the measurement of the amount of moisture vapor that passes through a substance over a given period. It relates to the permeation of moisture through packaging.

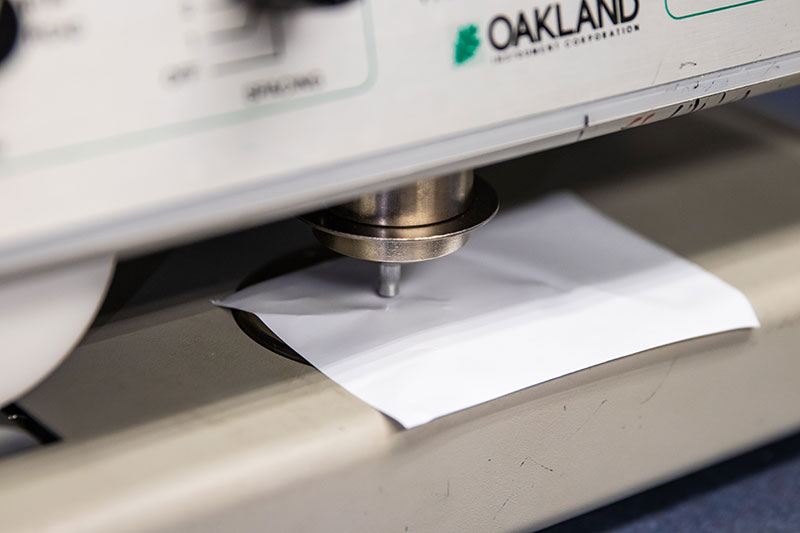

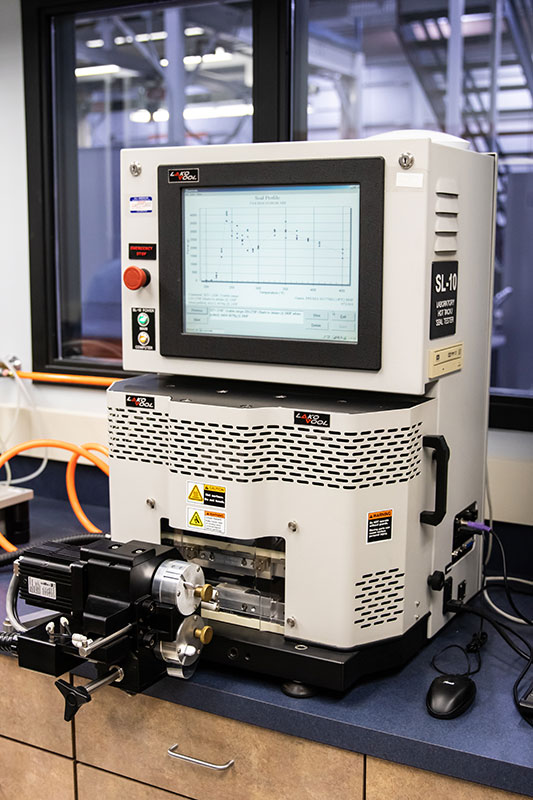

Hot Tack/SIT (Seal Initiation Temperature) Testing

Seal Initiation Testing provides an accurate and consistent method of testing the sealing properties of a wide range of packaging materials. Seal Initiation Testing provides an accurate and consistent method of testing the sealing properties of a wide range of packaging materials. PPI evaluates product seal strengths by performing Hot tack testing according ASTM F1921 (method B). Hot tack measures the strength of heat seals formed between thermoplastic surfaces of flexible webs, immediately after the seal has been made and before it cools to room temperature. This heat seal property is important since this situation occurs on vertical form-fill-seal packaging.

In the heat sealing process, contents are dropped into the bag immediately after the horizontal seal bars have opened. Since the content can be heavy, the hot seal must be able to withstand high loads, thus requiring a high hot tack force. This measurement will be of influence while upgrading packaging materials or packing production processes. Seal initiation temperature is defined as the heat sealing jaw temperature at which a specific level of seal strength is obtained and may be determined by plotting the seal strength versus seal jaw temperature.

We have the capability to simulate almost every imaginable sealing process configuration. This allows us to perfectly mimic the customers exact process parameters to ensure exact ‘fitness for use’ the first time!

Strain Gauge/Tensile Testing

One of our most essential data acquisition tools is the strain gage. Forces or loads are related to the stress in an object. Since stresses cannot be measured directly, it is easier to measure strains, the small amounts of stretching that occur in all materials when they are under load. With information about strain, the relationship between stress and strain can be used to determine the forces in an object. The most common reasons to apply strain gages include assessing the root causes of failures before products go to market.